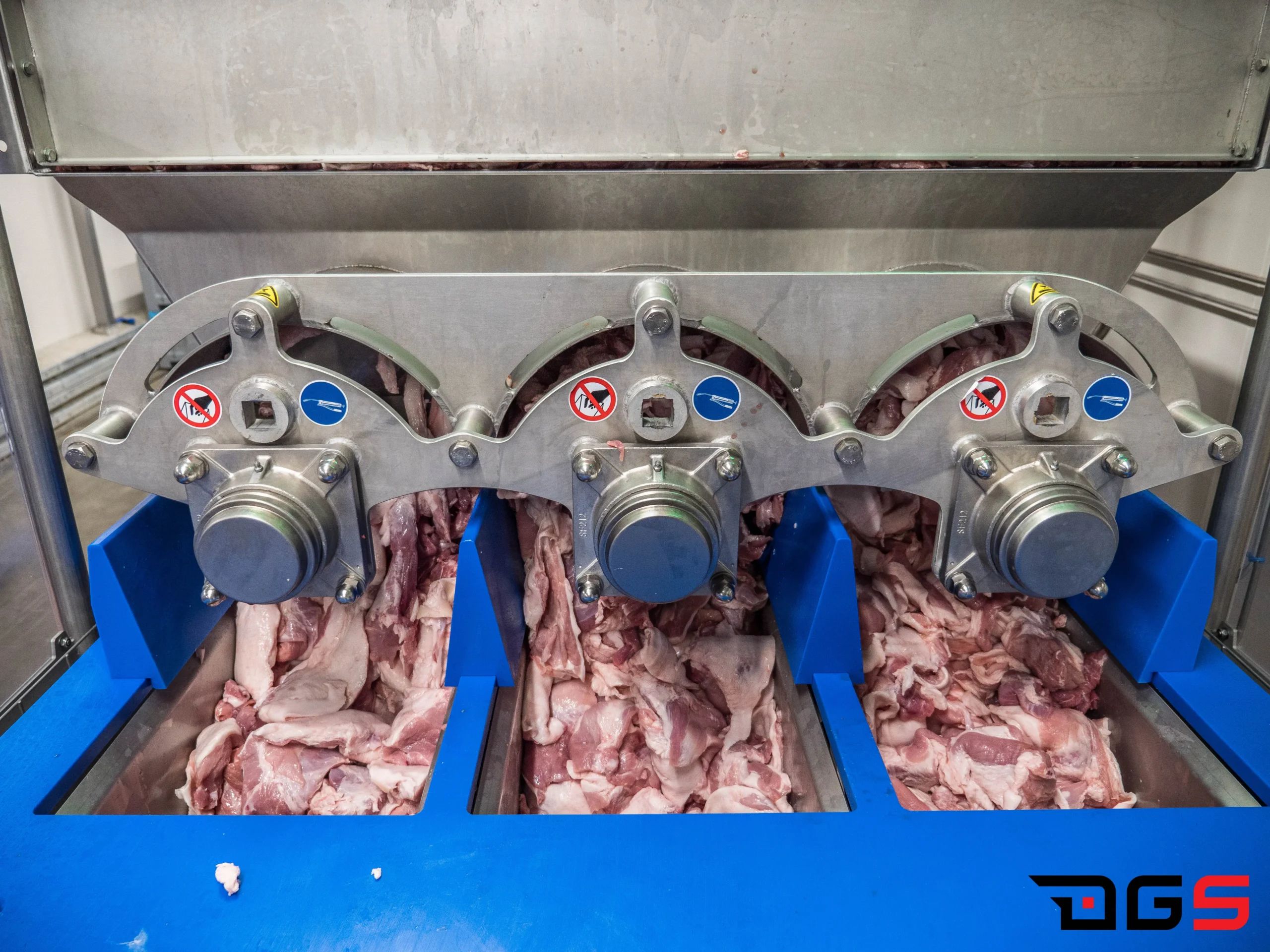

Automatic Weight-Based Hopper Filling

With the help of a hopper, filling plate freezers can be automated. The operator places a dolav in the tilting device, where the meat is evenly distributed to the weigh hoppers. Subsequently, the underlying cassettes are filled and moved to the appropriate row of the plate freezer, where the meat is dosed into the compartments. This results in a fixed block weight. If necessary, the operator can make adjustments for a final visual inspection of the product, leading to less waste and a consistent end product.

- Filling at a fixed block weight

- Minimization of waste and consistent end product

- Automatic filling and unloading

Depending on the products, we also offer an option for pump filling techniques.

Personal advice

We are happy to discuss the possibilities with you.

Automatic Unloading and Palletizing

After the freezing process is complete, the frozen blocks need to be removed from the freezers. Unloading the vertical freezer can be done in various ways; from manual to fully automated.

Manually, the operator can remove the blocks from the freezer and place them on a conveyor belt, which transports them to the robot palletizer. Another option is using an overhead crane equipped with a gripper capable of lifting a full plate freezer load and placing it on a block table. From there, the blocks are conveyed to the robot palletizer. At DGS, we offer various solutions, from filling to palletizing, to ensure an efficient and hygienic process.

More information